High-value concrete recycling plants

New income streams through CO2-based recycling of demolition concrete.

Add an upcycling step to your existing recycling value chain

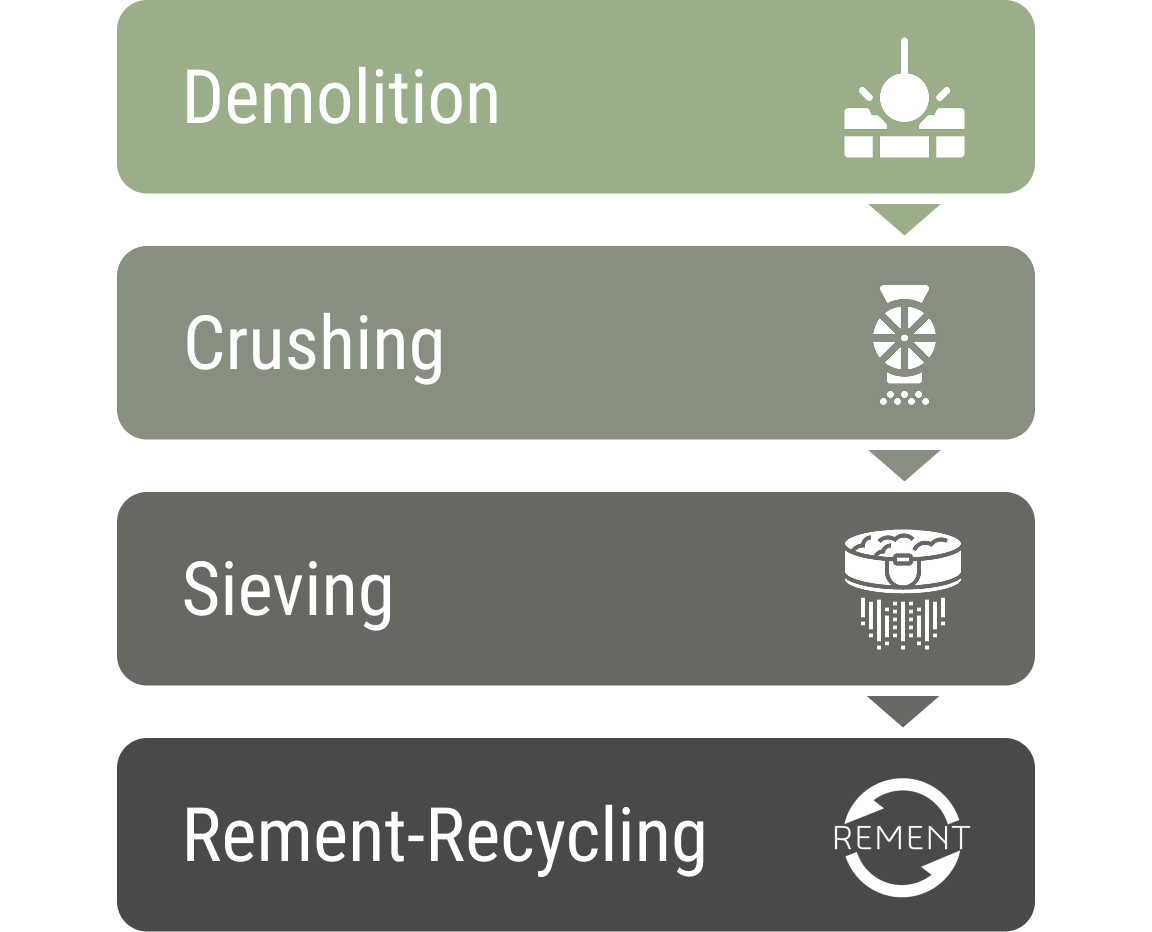

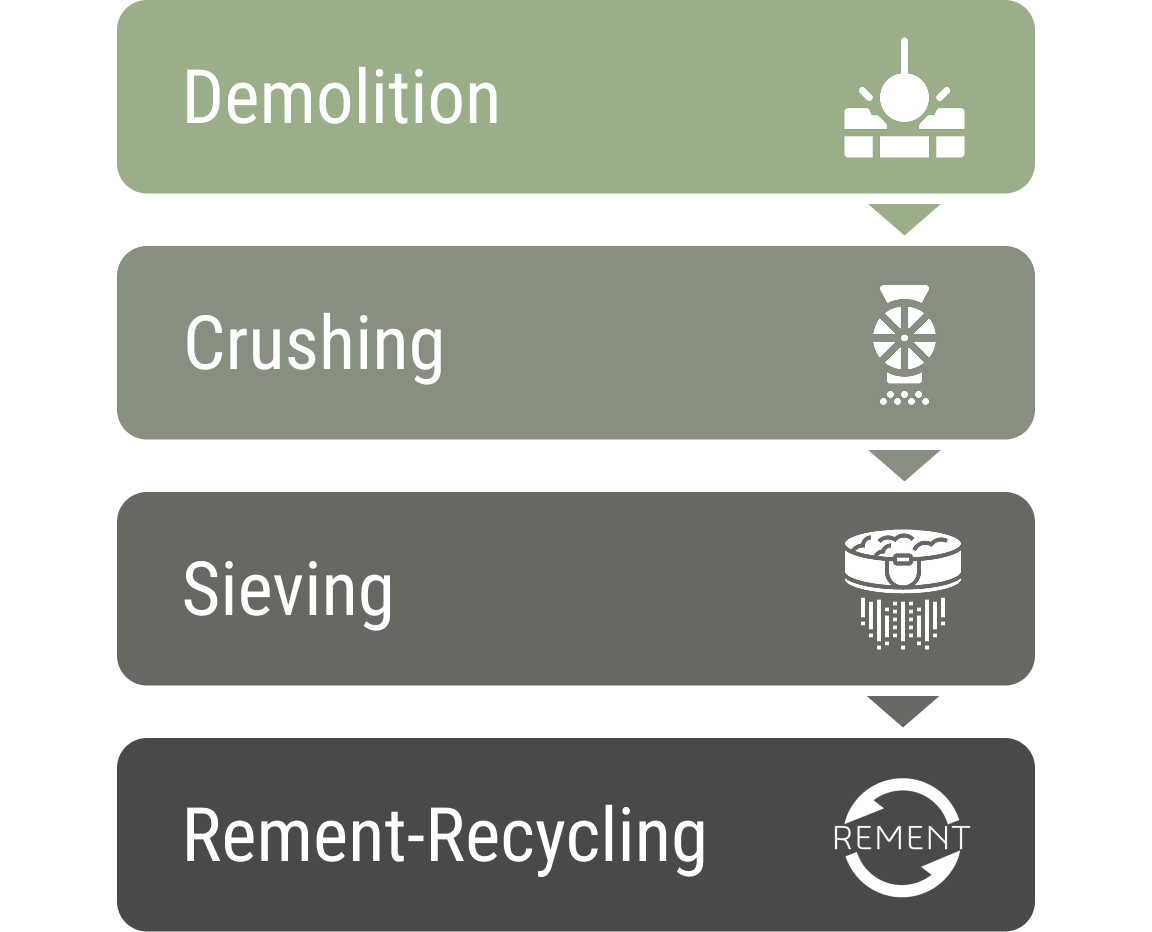

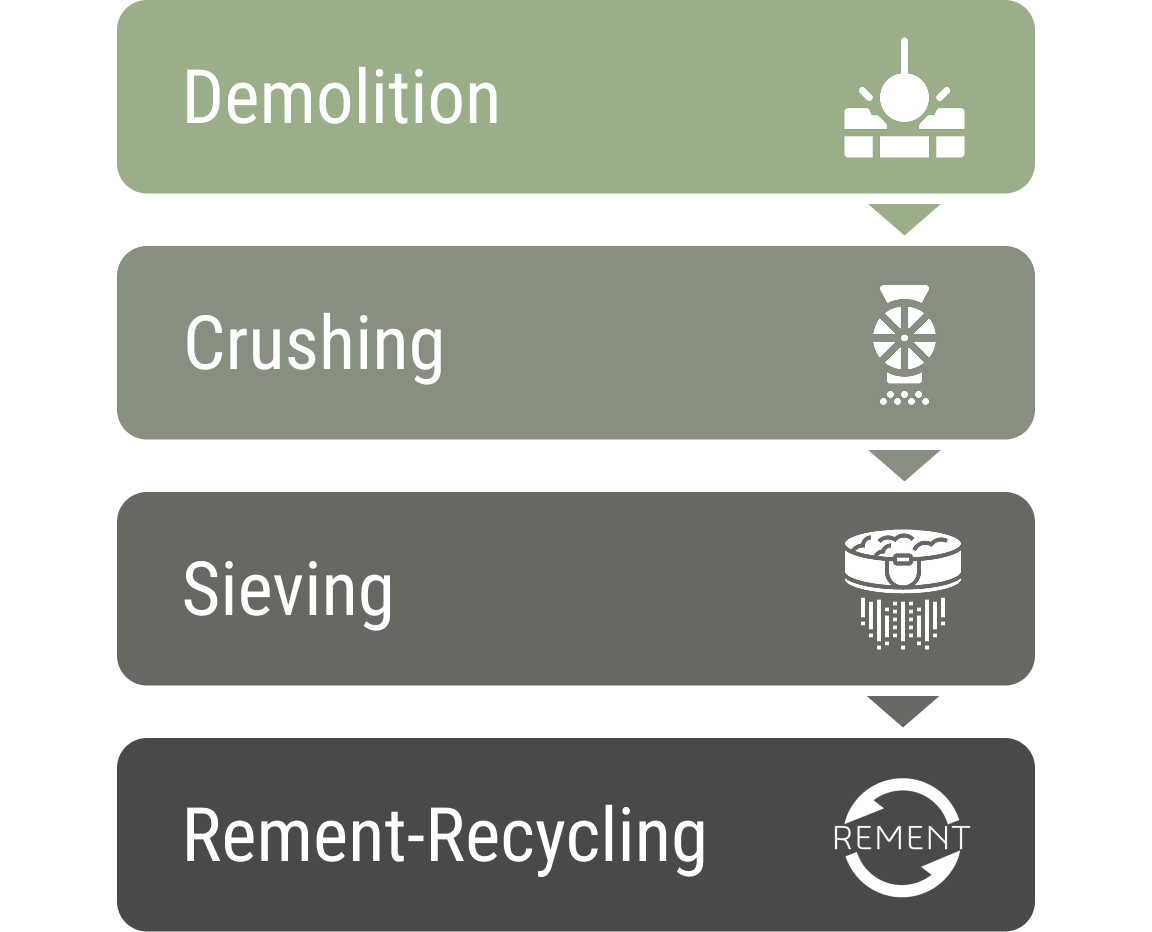

Demolish, Crush, Sieve

Rement plants will integrate seamlessly into existing concrete recycling value chains. As before, the demolition material will be crushed either on-site or at a stationary. The material should then be sieved to separate it into different grain sizes.

Further processing of concrete fines

Rement plants, located directly on the concrete recycling site, further process concrete fines 0/2 or 0/4. While this fraction currently has the fewest applications, its economic potential is particularly high, as it contains large amounts of cement stone. Our concrete recycling plants separate concrete fines into new products, while storing CO2. This CO2 can either be sourced from diluted exhaust gases or delivered in liquid form.

20 x increase in material value through high-purity separation

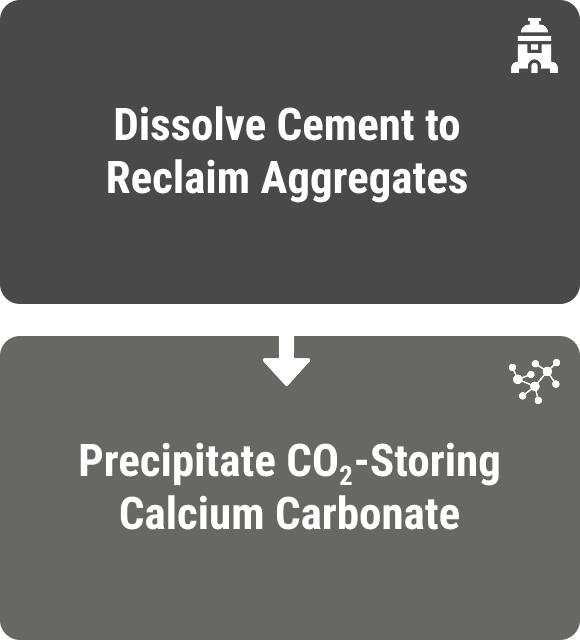

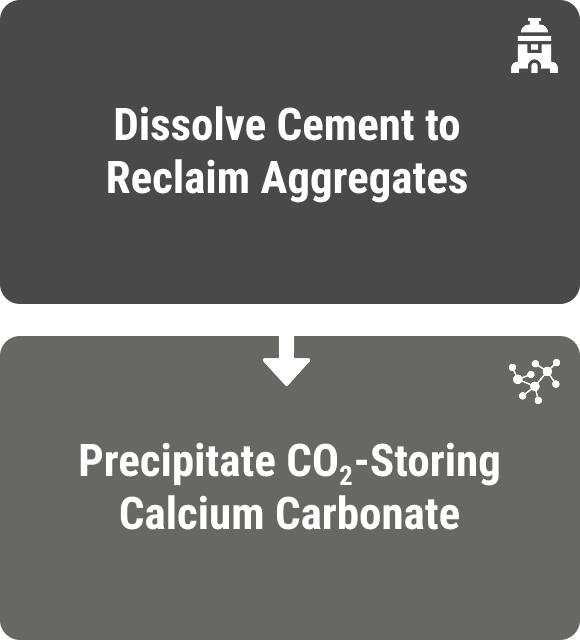

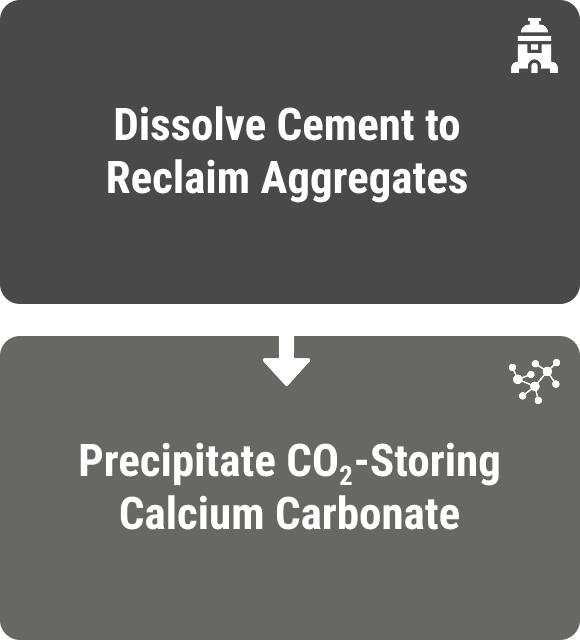

Dissolving Cement, reclaiming sand

We pierce deep into the crushed concrete sand and break down the cement compounds that hold the concrete together. As a result, we can recover the aggregates in different fractions for use in new concrete, precast elements, or construction chemical products.

Precipitating high-value calcium carbonate

The calcium oxide from the dissolved cement stone reacts with the carbon dioxide fed into the process. Under specifically controlled conditions, high-purity, fine calcium carbonate precipitates from the solution—ready for use as a color pigment and filler in construction chemical products, paint, plastics or paper.

Bring Concrete Recycling to a New Level - with Rement’s Technology at your Site

Let’s explore the potential

Access new revenues

Expand the range of applications by removing cement stone from your recycled aggregate and tap into the filler and pigment market by extracting precipitated calcium carbonate from the urban mine.

Become a decarbonizer

Access the carbon sink potential of your concrete waste and turn CO2 into products. Reduce your company's Scope 1 emissions—and your customers' Scope 3 emissions.

Invest into your future

Invest in your future by investing in concrete recycling plants. Thanks to the high material value generated, recycling plants can be amortized at an above-average rate.

High-value concrete recycling plants

New income streams through CO2-based recycling of demolition concrete.

Add an upcycling step to your existing recycling value chain

Demolish, Crush, Sieve

Rement plants integrate seamlessly into existing concrete recycling value chains. As before, the demolition material will be crushed either on-site or at a stationary. The material should then be sieved to separate it into different grain sizes.

Further processing of concrete fines

Rement plants, located directly on the concrete recycling site, further process concrete fines 0/2 or 0/4. While this fraction currently has the fewest applications, its economic potential is particularly high, as it contains large amounts of cement stone. Our concrete recycling plants separate concrete fines into new products, while storing CO2. This CO2 can either be sourced from diluted exhaust gases or delivered in liquid form.

20 x increase in material value through high-purity separation

Dissolving Cement, reclaiming sand

We pierce deep into the crushed concrete sand and break down the cement compounds that hold the concrete together. As a result, we can recover the aggregates in different fractions for use in new concrete, precast elements, or construction chemical products.

Precipitating high-value calcium carbonate

The calcium oxide from the dissolved cement stone reacts with the carbon dioxide fed into the process. Under specifically controlled conditions, high-purity, fine calcium carbonate precipitates from the solution—ready for use as a color pigment and filler in construction chemical products, paint, plastics or paper.

Bring Concrete Recycling to a New Level - with Rement’s Technology at your Site

Let’s explore the potential

Access new revenues

Expand the range of applications by removing cement stone from your recycled aggregate and tap into the filler and pigment market by extracting precipitated calcium carbonate from the urban mine.

Become a decarbonizer

Access the carbon sink potential of your concrete waste and turn CO2 into products. Reduce your company's Scope 1 emissions—and your customers' Scope 3 emissions.

Invest into your future

Invest in your future by investing in concrete recycling plants. Thanks to the high material value generated, recycling plants can be amortized at an above-average rate.

High-value concrete recycling plants

New income streams through CO2-based recycling of demolition concrete.

Add an upcycling step to your existing recycling value chain

Demolish, Crush, Sieve

Rement plants will integrate seamlessly into existing concrete recycling value chains. As before, the demolition material will be crushed either on-site or at a stationary. The material should then be sieved to separate it into different grain sizes.

Further processing of concrete fines

Rement plants, located directly on the concrete recycling site, further process concrete fines 0/2 or 0/4. While this fraction currently has the fewest applications, its economic potential is particularly high, as it contains large amounts of cement stone. Our concrete recycling plants separate concrete fines into new products, while storing CO2. This CO2 can either be sourced from diluted exhaust gases or delivered in liquid form.

20 x increase in material value through high-purity separation

Dissolving Cement, reclaiming sand

We pierce deep into the crushed concrete sand and break down the cement compounds that hold the concrete together. As a result, we can recover the aggregates in different fractions for use in new concrete, precast elements, or construction chemical products.

Precipitating high-value calcium carbonate

The calcium oxide from the dissolved cement stone reacts with the carbon dioxide fed into the process. Under specifically controlled conditions, high-purity, fine calcium carbonate precipitates from the solution—ready for use as a color pigment and filler in construction chemical products, paint, plastics or paper.

Bring Concrete Recycling to a New Level - with Rement’s Technology at your Site

Let’s explore the potential

Access new revenues

Expand the range of applications by removing cement stone from your recycled aggregate and tap into the filler and pigment market by extracting precipitated calcium carbonate from the urban mine.

Become a decarbonizer

Access the carbon sink potential of your concrete waste and turn CO2 into products. Reduce your company's Scope 1 emissions—and your customers' Scope 3 emissions.

Invest into your future

Invest in your future by investing in concrete recycling plants. Thanks to the high material value generated, recycling plants can be amortized at an above-average rate.

High-value concrete recycling plants

New income streams through CO2-based recycling of demolition concrete.

Add an upcycling step to your existing recycling value chain

Demolish, Crush, Sieve

Rement plants will integrate seamlessly into existing concrete recycling value chains. As before, the demolition material will be crushed either on-site or at a stationary. The material should then be sieved to separate it into different grain sizes.

Further processing of concrete fines

Rement plants, located directly on the concrete recycling site, further process concrete fines 0/2 or 0/4. While this fraction currently has the fewest applications, its economic potential is particularly high, as it contains large amounts of cement stone. Our concrete recycling plants separate concrete fines into new products, while storing CO2. This CO2 can either be sourced from diluted exhaust gases or delivered in liquid form.

20 x increase in material value through high-purity separation

Dissolving Cement, reclaiming sand

We pierce deep into the crushed concrete sand and break down the cement compounds that hold the concrete together. As a result, we can recover the aggregates in different fractions for use in new concrete, precast elements, or construction chemical products.

Precipitating high-value calcium carbonate

The calcium oxide from the dissolved cement stone reacts with the carbon dioxide fed into the process. Under specifically controlled conditions, high-purity, fine calcium carbonate precipitates from the solution—ready for use as a color pigment and filler in construction chemical products, paint, plastics or paper.

Bring Concrete Recycling to a New Level - with Rement’s Technology at your Site

Let’s explore the potential

Access new revenues

Expand the range of applications by removing cement stone from your recycled aggregate and tap into the filler and pigment market by extracting precipitated calcium carbonate from the urban mine.

Become a decarbonizer

Access the carbon sink potential of your concrete waste and turn CO2 into products. Reduce your company's Scope 1 emissions—and your customers' Scope 3 emissions.

Invest into your future

Invest in your future by investing in concrete recycling plants. Thanks to the high material value generated, recycling plants can be amortized at an above-average rate.